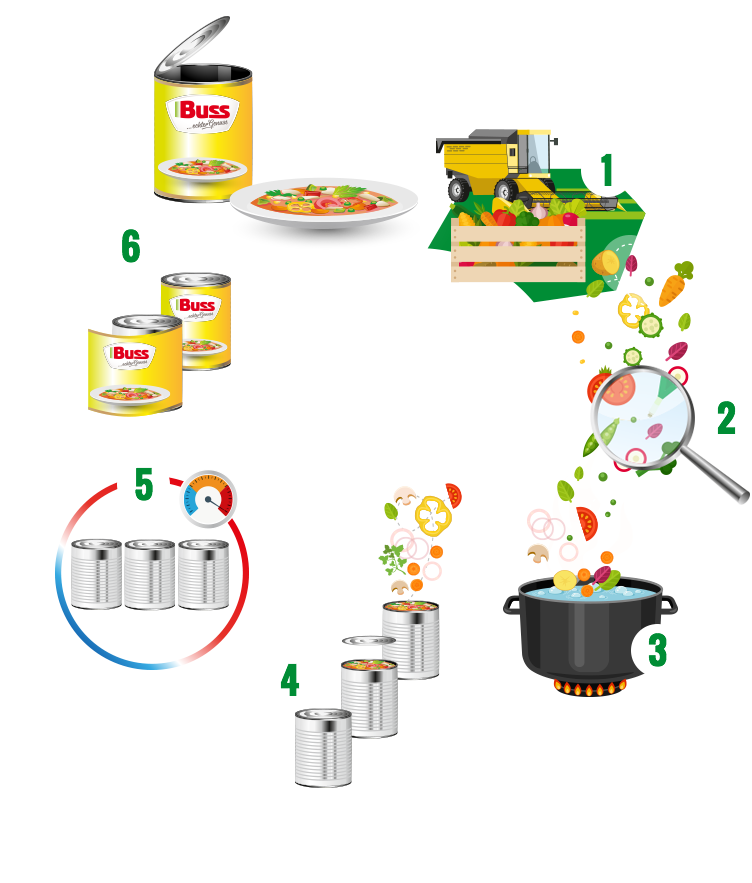

The production process

After the raw ingredients are delivered to our factory in Ottersberg and checked for their ideal quality and freshness, they are prepared for production in vegetable sorting, meat preparation and in the spice room. In the kitchen, mixtures are prepared from the various ingredients according to fixed recipes that have been taste-tested. These are automatically packaged. Delicate ingredients are added by hand.

After the tins or trays are filled with the raw materials, they are automatically closed and preserved. Food tins and shelf-stable tray meals are sterilised for a short period of time at a temperature of over 100° C. Pasteurization of the refrigerated tray meals takes place at approximately 98° C. The technology to preserve the food is similar to grandma’s preservation methods. Through modern overpressure methods (like in a pressure cooker), we are able to gently process the products and extensively maintain the vitamins and nutrients. And all of that without using preservatives!

After preservation, several final inspections are carried out to guarantee our optimal quality. Finally, the products are packaged, shipped and reach the end consumer via retail channels.

- Raw materials from selected cultivation regions are harvested.

- Through the high-quality cleaning operation, the products harvested from the field are cleaned.

- Carrying out the incoming goods inspection, as well as preparatory work for filling, such as blanching.

- Filling the products in food tins.

- Preservation: through a short period of heating in the can at more than 100° C in a pass-through steriliser.

- Can labelling.